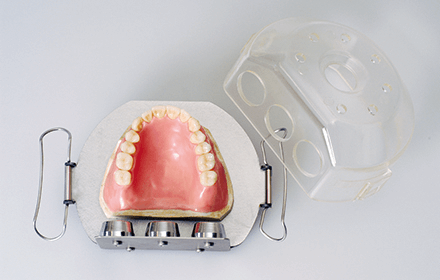

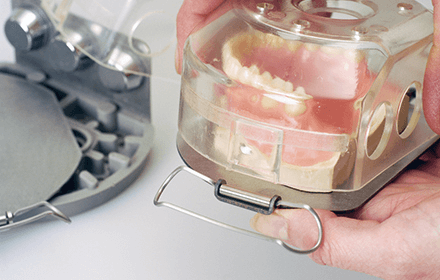

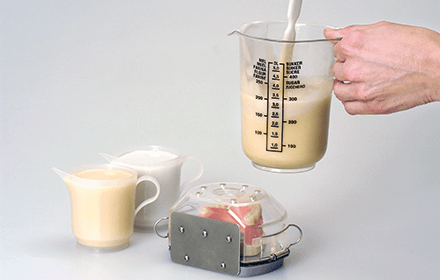

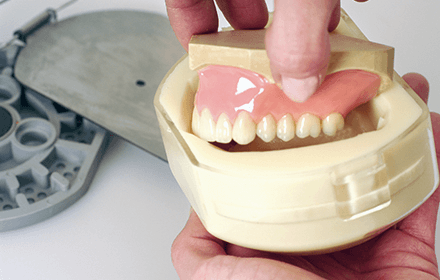

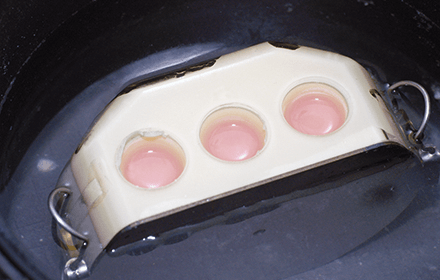

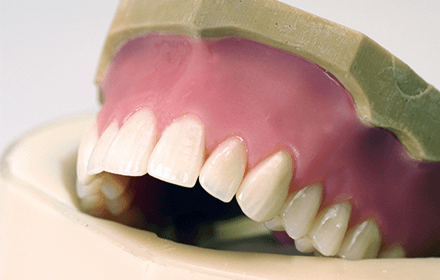

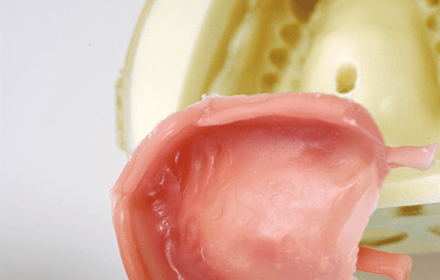

With Castdon we offer an unbeatabable, complete cold-curing system for the resin pouring technique. In contrast to the hot polymer, dentures made of Castdon resin have a significantly lower shrinkage. In addition, the processing is easier, faster and cleaner.