Our digital workflow provides a regulatory-compliant process, from data preparation to the finished component for your application.

Phrozen Sonic CS+ – Qualified by Dreve Compact LCD desktop printer with 22 μm resolution and an innovative 385 nm LED light source, delivering high light intensity for fast build times. The high-quality full-metal housing and improved vat and platform handling make the Phrozen Sonic CS+ a user-friendly 3D printer for all dental applications.

Cleaning unit for 3D printed parts after the print process. Device with magnetic stir technology and automatic transfer between the two cleaning containers. Various cleaning programs can be selected and set via touchscreen. The platform of the Sonic CS+ can be directly hooked into the device and cleaned together with the attached parts.

Laboratory device based on LED technology for curing 3D printed parts. Ensures mechanical properties and biocompatibility through effective depth curing. The PCU vario 160 offers both, the option of a vacuum atmosphere and the possibility of curing under nitrogen. Biocompatible curing without an inhibition layer can be ensured.

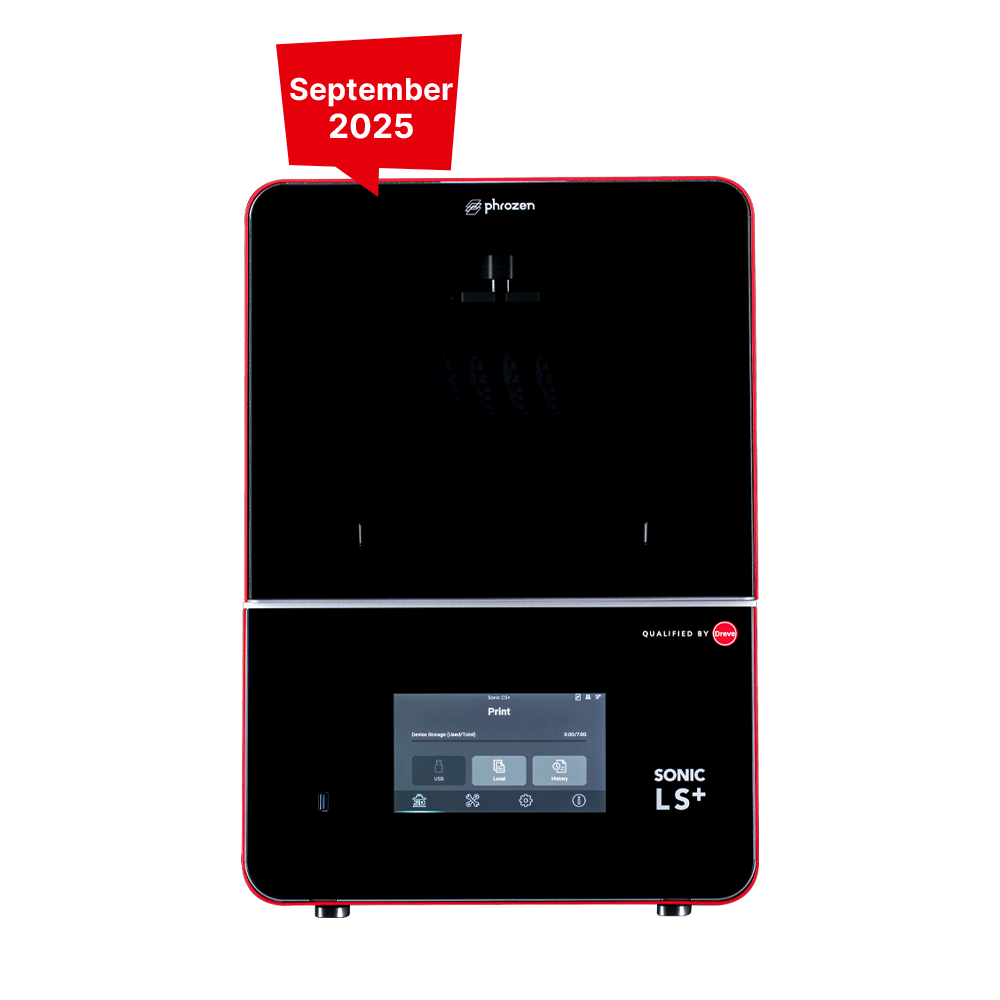

The Phrozen LS+ sets new standards for laboratory use. With its 385 nm LED light source and a large building platform of 209 x 133 mm², all dental applications can be produced with precision and high speed. The high-quality full-metal housing, elegant glass fronts, and an illuminated build chamber with a camera ensure a comfortable and user-friendly experience at all times.

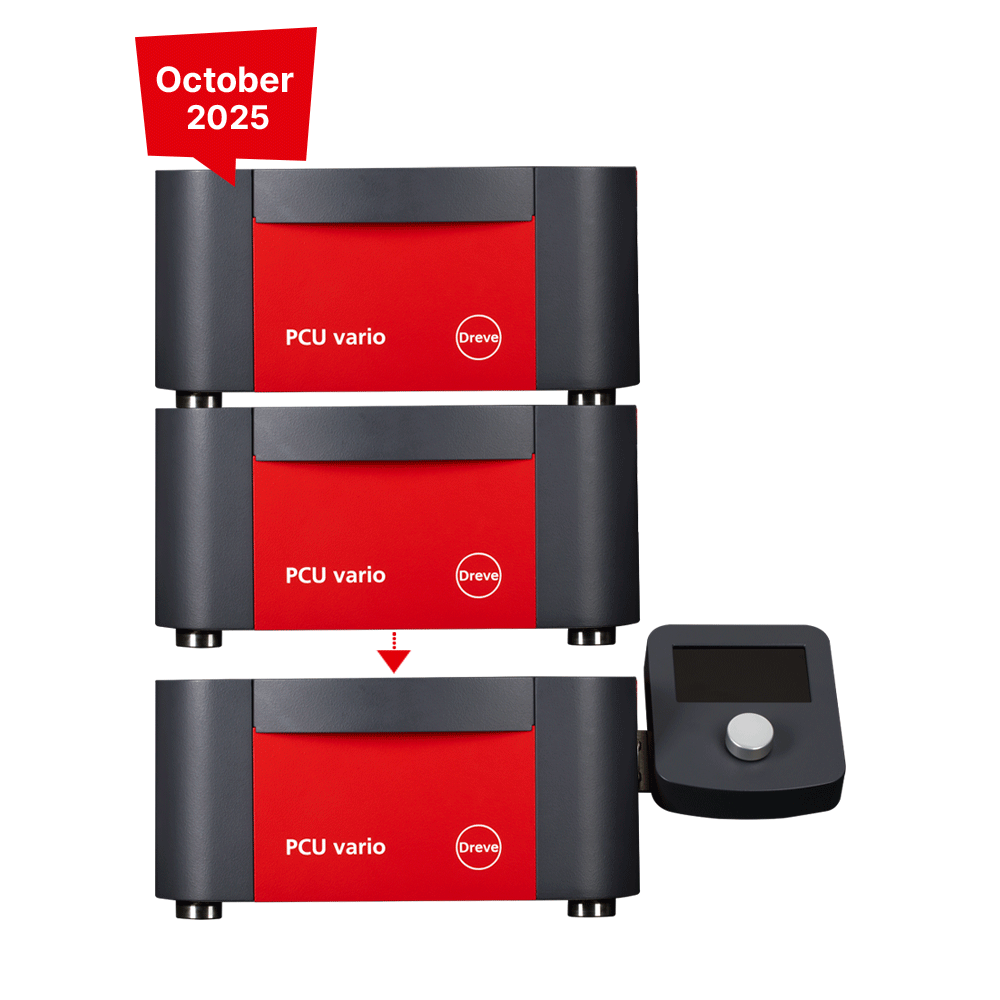

The PCU vario 40 is Dreve’s new high-end post-curing unit. The use of three wavelengths and high light intensity ensures fast and biocompatible post-curing processes. Thanks to the nitrogen atmosphere, even light distribution in the chamber, and the ability to connect up to three curing chambers to a single control unit, processes run efficiently – all while requiring minimal space.

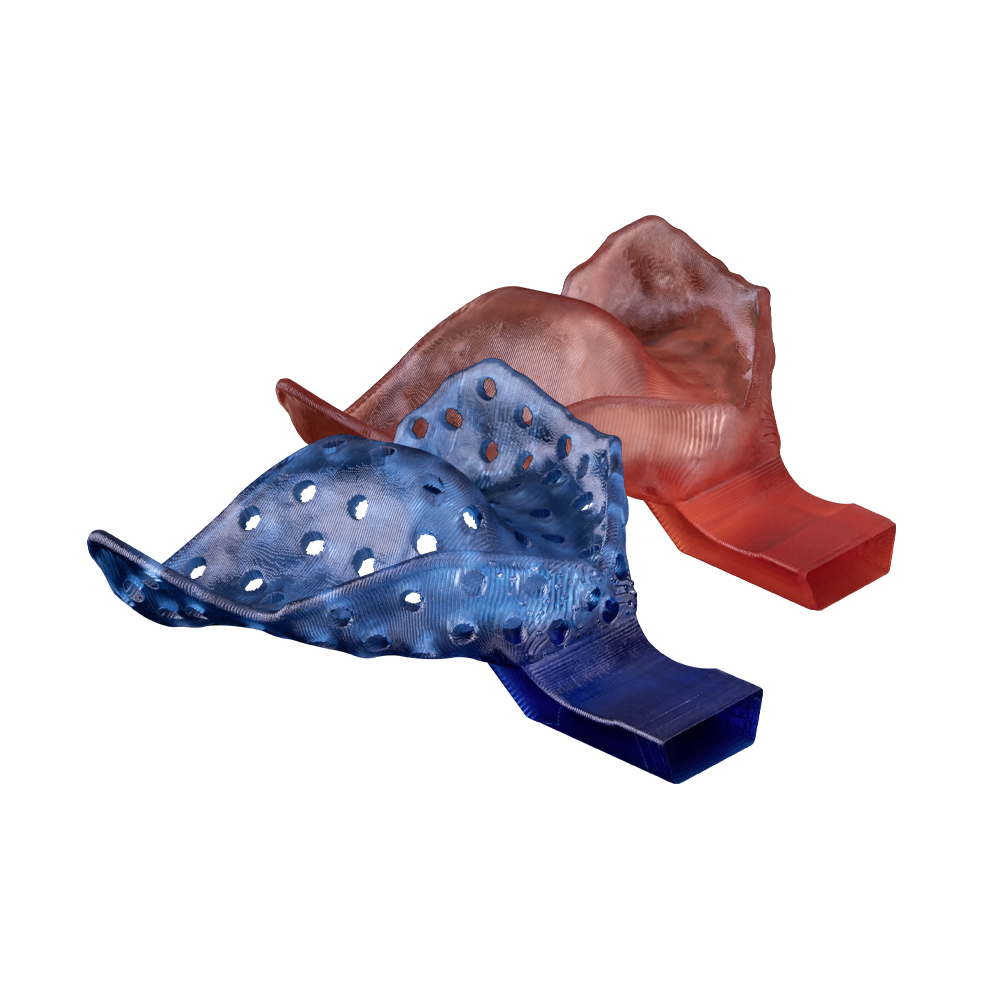

Optimized, biocompatible resin for the fabrication of individual dental impression trays. High reactivity with low viscosity. Simplified cleaning and improved mechanical properties. Twice as fast printing times, layer thicknesses of 300 µm possible. The resulting impression trays exhibit a homogeneous surface, minimizing the need for manual post-processing.

FotoDent® model3 is the latest version of the dental model range. It can be processed on all common DLP and LCD printing systems. The printed dental application can be easily cleaned with water after production and impresses with high dimensional precision. Available in gray and beige-opaque.

Light-curing model resin that is made of 50 percent renewable raw materials. The material properties are naturally optimally aligned for model production (including in the aligner workflow). FotoDent® biobased model can be cleaned with FotoClean.

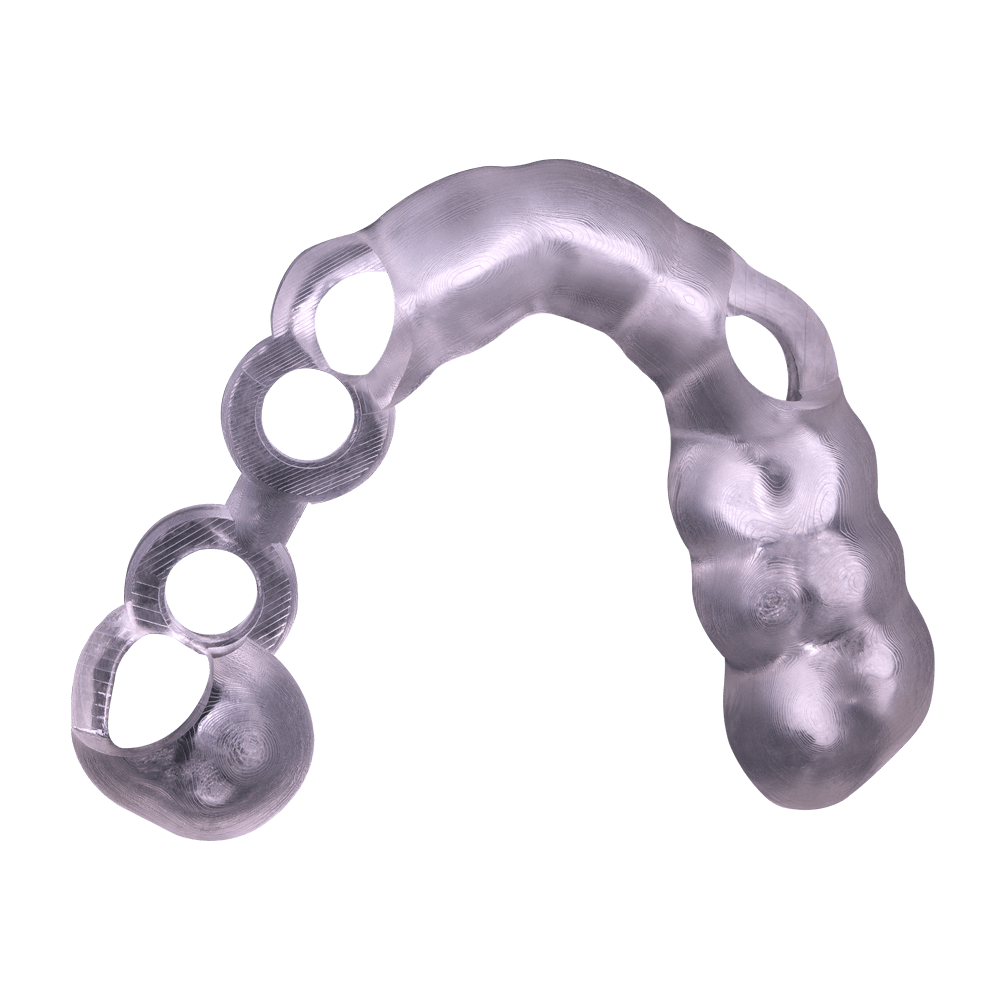

Light-curing resin for the fabrication of dental drilling splints. Splints made from FotoDent® guide are dimensionally stable and biocompatible. Available in colorless-transparent (385 nm) and blue-transparent (405 nm).

Light-curing resin for the production of denture bases. The use of the resin ensures accurate results with maximum dimensional stability. FotoDent® denture is free of MMA and color-stable.

Separator for 3D-printed resin models used with autopolymerizing materials. Provides optimal insulation for the spraying process in orthodontics or for the fabrication of prostheses including those made from Castdon.